Carbon Neutrality

To hand down the beautiful earth to the future is a task shared by the international community and also a major challenge. The TANAKA is pursuing every possibility to minimize the environmental impact of its business activities.

Statement on Carbon Neutrality

The TANAKA will take on the challenge of addressing global warming, a social issue on a global scale, by aiming to achieve carbon neutrality by 2050 and actively introducing technologies that contribute to a decarbonized society within the Group and in society.

To reduce greenhouse gases arising from business activities, we will continuously undertake emission reduction activities, such as increasing energy efficiency, improving manufacturing processes and adopting the use of green energy, at our plants and offices.

At the same time, we will provide products that meet the expectations of customers working toward a decarbonized society, including catalysts that contribute toward greenhouse gas reduction and high-performance materials such as those used in electric vehicles. We will also strengthen our precious metal recycling business to contribute toward a circular economy, thereby creating a prosperous and sustainable future for the Earth with our own hands.

We will consider tree-planting and activities to preserve forest rejuvenation such as the creation of Tanaka Forest.

The TANAKA aims to achieve carbon neutrality through these activities.

In fiscal 2022, we will form a company-wide project team directly controlled by the CEO to consider and implement specific measures. The TANAKA will continue to provide value to customers and society as a whole through products and solutions that apply the unique characteristics of precious metals.

TANAKA

Group CEO

Commitment to the Prevention of Global Warming

The TANAKA sets a target of reducing per-unit energy consumption in domestic bases by 1% each year to conform to the Act on the Rational Use of Energy of Japan.

Energy Consumption and Per-unit Energy Consumption by Year (in Japan)

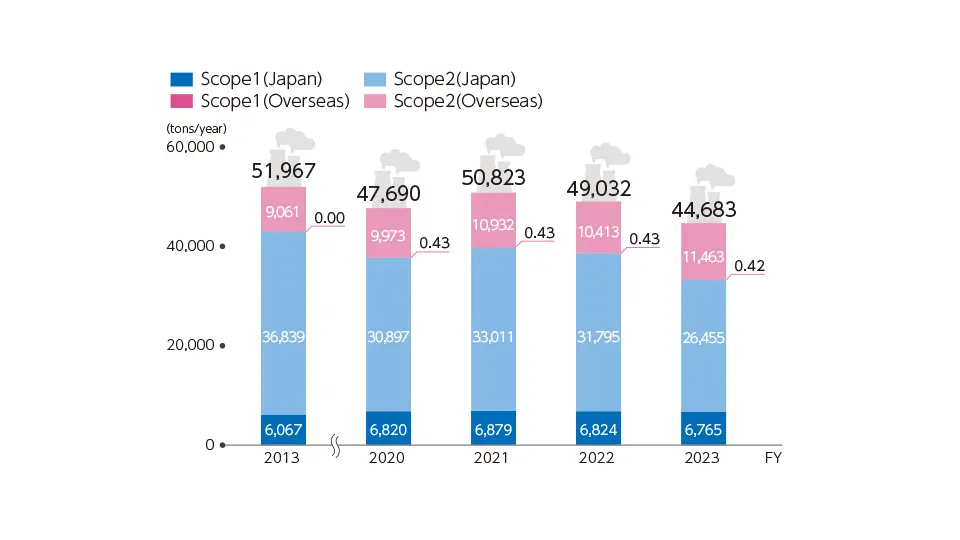

CO₂ Emissions by Year (global)

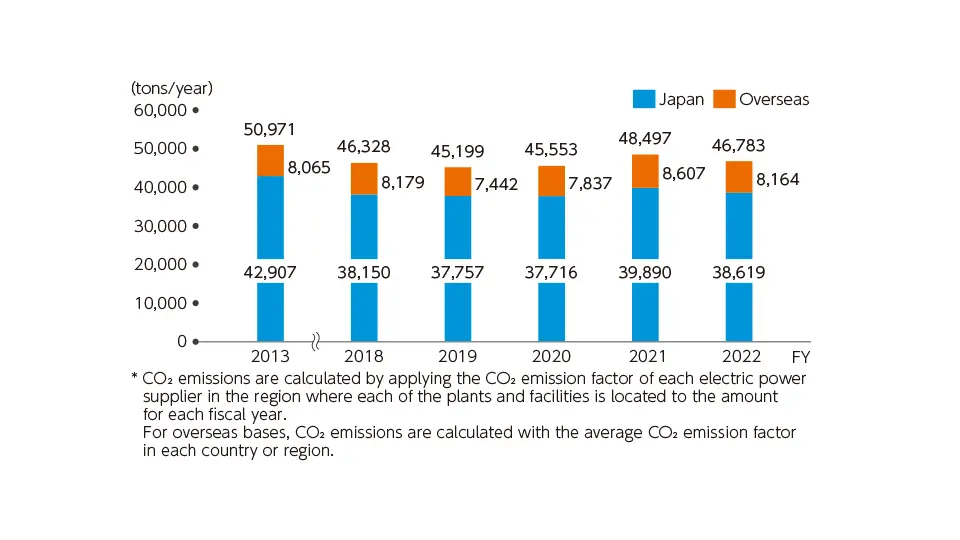

CO₂ Emissions by Facility (in fiscal 2022)

| Plant | CO₂ emissions (tons) |

|---|---|

| Shonan Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 7,878 |

| Tomioka Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 6,288 |

| Sodegaura Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 4,694 |

| Ichikawa Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 4,023 |

| Hiratsuka Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 3,876 |

| Tsukuba Facility of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 3,672 |

| Isehara Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 2,994 |

| Iwate Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 2,453 |

| TANAKA Electronics (Hangzhou) Co., Ltd. (TEC) | 2,238 |

| TANAKA Electronics Singapore Pte. Ltd. (TES) | 1,699 |

| TANAKA Electronics Malaysia Sdn. Bhd. (TEM) | 1,589 |

| Saga Production Headquarters of TANAKA ELECTRONICS Co., Ltd. | 1,221 |

| Hsinchu Plant of Taiwan TANAKA Kikinzoku Kogyo Co., Ltd. | 1,101 |

| Hukou Plant of Taiwan TANAKA Kikinzoku Kogyo Co., Ltd. | 877 |

| TANAKA Electronics Taiwan Co., Ltd. (TET) | 661 |

| EEJA Ltd. | 561 |

| Other | 959 |

Introduction of Photovoltaic Power Generation

Mitomo Semicon Engineering Co., Ltd. introduced photovoltaic power generation in fiscal 2022. While the operation started in the middle of the fiscal year, the introduction resulted in an 8% reduction of annual energy consumption in the whole plant in fiscal 2022.

List of the Plants That Have Introduced Photovoltaic Power Generation

| Plant | Energy reduction effect |

|---|---|

| Shonan Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 1% |

| Tomioka Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 3% |

| Hiratsuka Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 2% |

| Tsukuba Facility of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 4% |

| Isehara Plant of TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. | 4% |

| Saga Production Headquarters of TANAKA ELECTRONICS Co., Ltd. | 3% |

| Mitomo Semicon Engineering Co., Ltd. | 8% |

TOPICS

Metalor Technologies SA, a Group company, has introduced photovoltaic power generation at its bases in Switzerland, France, the US, Mexico, China and Hong Kong and reduced CO₂ emissions in the Metalor Group as a whole by 13%.