Gold is a precious metal in extremely short supply on our planet. In fact, only about 190,040 tons of gold have ever been mined in recorded history, which equates to about 4 swimming pools. And the majority of that gold was extracted from ore taken from gold mines.

Gold ore includes platinum, silver and other precious metals apart from gold. The process of separating the gold begins by crushing the gold ore into a fine powder. Chemicals are then used to extract a solution of gold and other valuable components. The solution (pregnant solution) is placed in an electrolytic bath where difficult-to-ionize gold, platinum, silver and other elements are deposited out of the solution. The extract is then melted down in a high-temperature oven, where high specific gravity gold settles to the bottom and can be separated. At this point, the gold is 98% pure.

After repeated refining, the purity of the gold increases to 99.99% and that is what is used to manufacture gold bullion ingots.

Japan once had its share of gold mines with high concentrations of gold, but with not enough gold remaining to make mining profitable any more, the majority of those mines are now closed.

In Japan, instead of gold mining, Urban Mining is currently attracting a lot of interest. In fact, there is a vein of gold running through towns and cities that carries much more gold than that left in gold mines. That gold is in our computers, cell phones, digital cameras, game machines and other devices. Of the precious metals, gold is the least susceptible to corrosion and degradation, and because it can be stretched into fine filaments or thin leaf and is highly conductive of electricity, it is also an essential part of precision manufactured products. Only a very little gold is used in a single product, but when all collected together it rivals that collected from a huge mine, so we call this recovery process Urban Mining.

TANAKA Kikinzoku Kogyo is able to recover precious metals from Urban Mining in Japan, from which it refines high purity gold. This recycling process is explained below.

Gold ore includes platinum, silver and other precious metals apart from gold. The process of separating the gold begins by crushing the gold ore into a fine powder. Chemicals are then used to extract a solution of gold and other valuable components. The solution (pregnant solution) is placed in an electrolytic bath where difficult-to-ionize gold, platinum, silver and other elements are deposited out of the solution. The extract is then melted down in a high-temperature oven, where high specific gravity gold settles to the bottom and can be separated. At this point, the gold is 98% pure.

After repeated refining, the purity of the gold increases to 99.99% and that is what is used to manufacture gold bullion ingots.

Japan once had its share of gold mines with high concentrations of gold, but with not enough gold remaining to make mining profitable any more, the majority of those mines are now closed.

In Japan, instead of gold mining, Urban Mining is currently attracting a lot of interest. In fact, there is a vein of gold running through towns and cities that carries much more gold than that left in gold mines. That gold is in our computers, cell phones, digital cameras, game machines and other devices. Of the precious metals, gold is the least susceptible to corrosion and degradation, and because it can be stretched into fine filaments or thin leaf and is highly conductive of electricity, it is also an essential part of precision manufactured products. Only a very little gold is used in a single product, but when all collected together it rivals that collected from a huge mine, so we call this recovery process Urban Mining.

TANAKA Kikinzoku Kogyo is able to recover precious metals from Urban Mining in Japan, from which it refines high purity gold. This recycling process is explained below.

At TANAKA Kikinzoku Kogyo, we recover precious metals from such things as electronic equipment and other industrial scrap, liquid waste from factories, and precious metals jewelry.

There is no shortage of very thin gold plate in integrated circuits and other semiconductors, in aluminum plate and other parts. And some components of the hard disks in computers use gold, platinum, silver and other precious metals. Even the plastic containers used to hold precious metals have minute traces remaining after use.

There is no shortage of very thin gold plate in integrated circuits and other semiconductors, in aluminum plate and other parts. And some components of the hard disks in computers use gold, platinum, silver and other precious metals. Even the plastic containers used to hold precious metals have minute traces remaining after use.

Liquid waste from gold plating also has some gold left in solution. That includes liquids used for plating semiconductors and other products. During the manufacturing process for electronic devices, these liquids are used for extracting precious metals. By processing these precious metals sources, TANAKA is able to extract high purity gold.

In this process, the collected precious metals jewelry, industrial scrap and other source metal is placed in a mixed acid solution called aqua regia, which is generally a mixed solution of nitric acid and hydrochloric acid in a volume ratio of 1:3. This has an extremely strong oxidizing power that dissolves most precious metals including gold. On the other hand, it does not dissolve plastics and other resins.

The aqua regia solution with its dissolved gold is transferred to a reduction tank.

Of the precious metals, gold is the least susceptible to corrosion. This means that oxygen does not adhere easily to gold, and so gold is difficult to oxidize. In aqua regia though, gold dissolves after losing electrons and becoming ionized. An easily oxidizable substance (reducing agent) is then added to this solution, at which point electrons are supplied and the gold becomes deionized and resolidifies into the precious metal. This process is called reduction. The reduced gold becomes powder in a solution that looks like muddy water.

The aqua regia solution with its dissolved gold is transferred to a reduction tank.

Of the precious metals, gold is the least susceptible to corrosion. This means that oxygen does not adhere easily to gold, and so gold is difficult to oxidize. In aqua regia though, gold dissolves after losing electrons and becoming ionized. An easily oxidizable substance (reducing agent) is then added to this solution, at which point electrons are supplied and the gold becomes deionized and resolidifies into the precious metal. This process is called reduction. The reduced gold becomes powder in a solution that looks like muddy water.

The next step is to filter the gold powder out of the solution. The extracted gold powder still has some water content at this point, so purity is between 99% and 99.9%. Instead of being golden colored though, the gold powder is brown.

There is still some reducing agent left in the gold powder as well, so it must be washed out.

There is still some reducing agent left in the gold powder as well, so it must be washed out.

After washing the gold powder, it must be dried. The resulting powder is smooth and dry, at a purity of between 99% and 99.9%.

Finally, by repeating the aqua regia dissolution and reduction process a second time, we are able to improve purity to 99.99%.

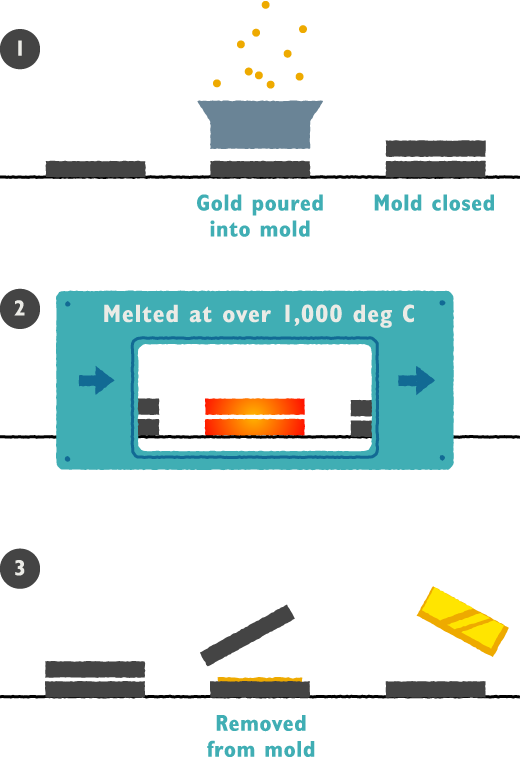

The gold powder is placed in a piece of equipment for melting at up to approximately 1,200 degrees Celsius (the melting point of gold is 1064.43 degrees Celsius).

The melted gold is then cooled down inside the equipment where it forms uniform beads about half the size of a grain of rice. These beads of gold are called shot.

The melted gold is then cooled down inside the equipment where it forms uniform beads about half the size of a grain of rice. These beads of gold are called shot.

Once the shot is created, the gold gleams with a brilliant golden color. One characteristic of gold is that it absorbs a wide spectrum of light. In other words, it absorbs light in the green to purple ranges and only reflects the remaining red to yellow light. This reflected light is what gives gold its golden color. Gold is the only precious metal that has this high absorption range.

By melting the gold shot again and crystallizing the gold, we are able to further increase the purity. At this point, we can cast the gold into 99.999% pure (five nines) gold ingots.

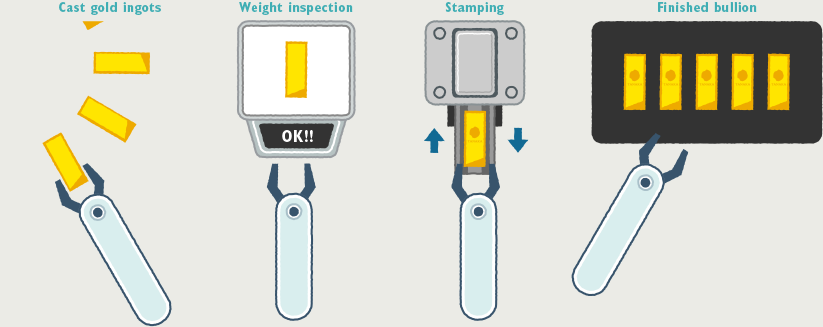

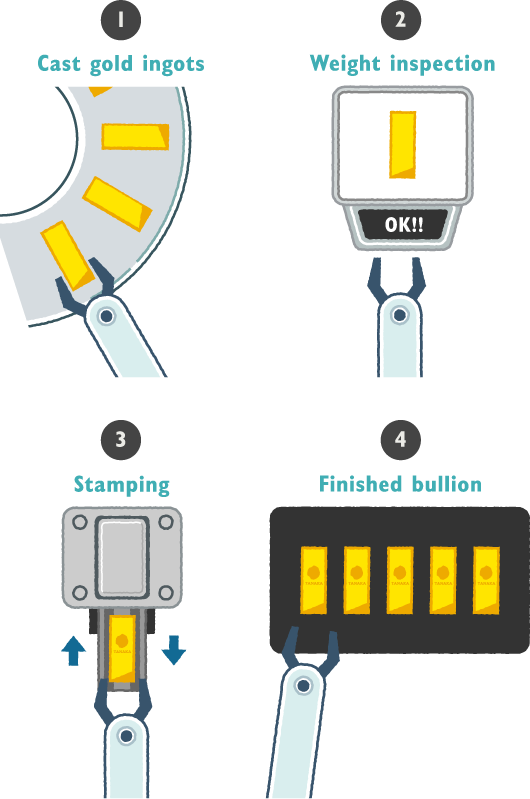

Gold bullion ingots are made by melting gold shot and solidifying it in a mold. Gold bullion is normally 99.99% pure.

Each finished gold bullion ingot undergoes highly accurate inspections and measurements before it is finally complete. TANAKA Kikinzoku’s gold bullion is stamped with the authorized melter’s mark of The London Bullion Market Association, which is the most prestigious authority in the global market.